Insights

Port Disruptions Are the New Norm

On Wednesday of this week, China closed a crucial terminal at its Ningbo-Zhoushan port, the third-busiest port in the world, after positive COVID-19 tests of workers. This occurred at the same time that nearby Shanghai ports are seeing their worst port congestion in three years, according to Reuters.

These shutdowns come when shipping rates are already significantly elevated, putting pressure on companies that rely on goods from overseas, and forcing prices for key products like electronics, food, and furniture even higher.

Shipping container rates from China and East Asia to the West and East coasts of the US have jumped over 270% and 220%, respectively, this year, according to the Freightos Baltic global container freight index.

Global supply chain disruptions are now the norm, not the exception, which is causing more companies to implement localization strategies. NAC is working with Siemens and Deloitte Consulting to help companies localize their manufacturing and supply chains, because global shipping won’t improve anytime soon.

Supply Chain Attacks Could Total Hundreds of Billions In Losses

At a recent Black Hat conference, it was concluded that supply chain cyberattacks will increase exponentially during the coming years, creating national security threats and hundreds of billions of dollars in private sector losses.

The recent SolarWinds, Kaseya and Colonial Pipeline cyberattacks are examples of costly supply chain attacks where hackers exploit vulnerabilities and compromise internal networks and data. The hackers then demand a ransom be paid to restore the company’s systems and data. Damage caused by these attacks can be significant. The Colonial Pipeline attack took down the largest fuel pipeline in the U.S. and led to shortages across the East Coast.

While some of these attacks are sophisticated, others are quite basic and most cyberattacks are preventable. The Colonial attack resulted from a single compromised password. Every business and every person relies on supply chains. Given the likelihood that we will see many more of these attacks, it’s imperative that companies (1) harden their technology; (2) carefully train their employees regarding cyber security procedures; (3) utilize predictive tools to prevent problems before they occur; (4) move critical path technology to non-cloud, firewall protected off-grid networks that can operate locally; and (5) obtain sufficient cybersecurity insurance coverage.

China’s Dirty Solar Secret May Soon Benefit America

Megawatt-scale solar farms are currently the most popular form of renewable energy production in the U.S. and Europe.

However, there is a dark cloud with a potential silver lining on the horizon — most solar panels are produced in China with energy provided by coal-fired power plants. Some say that this makes the solar industry hypocritical and potentially one of the world’s most prolific polluters.

Coal-fired electricity is provided by China to solar panel producers at very low cost, giving them a competitive pricing advantage in the global marketplace. China also uses dirty power to produce more than 75% of the world’s polysilicon, a key material used in most solar panels.

The U.S. government is drafting a policy to favor purchase of solar panels that are made using cleaner energy in America. The European Union is expected to soon regulate the carbon content of solar panels sold throughout the 27-nation EU. These policies would not only promote decarbonization, but also help develop a growing solar energy manufacturing industry in America.

Kryptonite of Broken Supply Chains Can Be Neutralized With Localization and Technology

Leadership and team members at any company, regardless of size, know that ongoing pandemic-related supply chain imbalances are costly. Sales are up at many companies, but profit is down, primarily because higher transportation costs and delays are eating into profits.

Broken global supply chains won’t be fixed anytime soon, so what should companies do? There are three things companies can do now to address supply chain issues and improve their profitability.

Localize Operations

It may not be feasible or cost-effective for companies to relocate all of their physical locations, but in certain circumstances, the closer a company can be to its suppliers and/or customers, the better. Localization is effectively an “insurance policy” against supply chain disruptions and ever-increasing transportation costs. Localization also allows more efficient and predictable operations.

Utilize Digital Planning and Efficiency Tools

Digitalization is the process of connecting digitized information via digital tools, such as digital twins to transform business processes and create new opportunities for product innovation. Digitalization is affordable and widely available to help companies model, analyze and optimize the flow of operations. Digitalization can benefit any company — even older facilities can be optimized using digital tools.

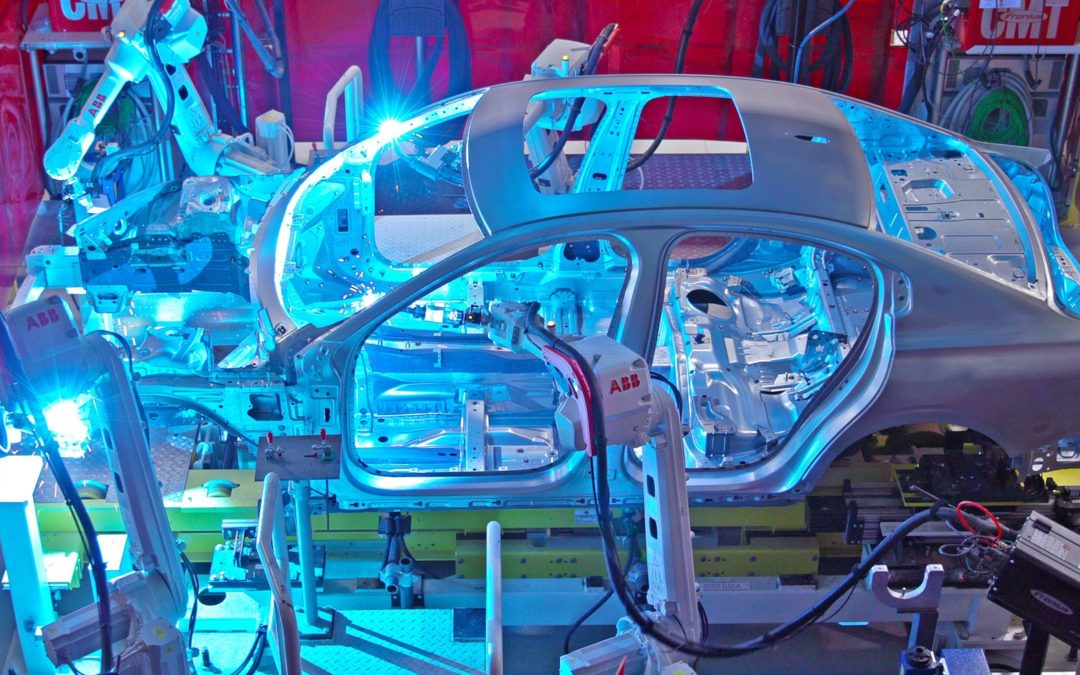

Automate

Smart processes help companies analyze and utilize real-time data to optimize operations. Sensors, data collection, automation using robots and cobots, interactive internal and external communication, and other automation advantages can result in double-digit percentage improvements in efficiency and profitably.

In conclusion, the business world has changed forever, and those companies that are willing to step into the future by adopting modern technology and tools, will outperform their competition. https://www.automation.com/en-us/articles/july-2021/improving-operations-localization-solutions

Volvo and Tesla Are Ahead of the Competition

Volvo plans to modify its Ridgeville, South Carolina factory, which is located less than 40 miles from Charleston, to become a dedicated EV factory. Volvo CEO Hakan Samuelsson said that the factory will be the first Volvo factory in the world making only electric cars. This makes Tesla and Volvo the only carmakers in the US with factories dedicated solely to manufacturing EVs.

The South Carolina factory will initially serve as an export hub for the electric XC90. The next-generation XC90 will be produced with a novel approach—essentially allowing the same vehicle to be built on two platforms. As Volvo’s de facto flagship, it will also introduce new technologies, such as integrated lidar and more advanced driver assist technology.

The XC90 will be followed in 2024 by an electric version of the smaller XC60 SUV. Sibling brand Polestar will also build the all-electric Polestar 3 in South Carolina as well, with deliveries starting in 2022.

Volvo is building a European battery factory with Swedish company Northvolt that will initially supply batteries for Europe. It’s possible that a similar dedicated battery factory could also be built in the U.S.

Contact Us